Have you ever wondered how oil, gas, and water can flow together through pipelines without mixing into one substance? Or how blood carries both liquid plasma and solid cells seamlessly through your body?

The answer lies in something called a Multi Phase Formula. Understanding this concept isn’t just for scientists or engineers—it can unlock insights into everyday processes and technologies that impact your life. You’ll discover what a Multi Phase Formula is, why it matters, and how it plays a crucial role in industries and natural systems around you.

Keep reading to uncover the fascinating world of multiple phases moving together and why grasping this idea could change the way you see the flow of things.

Credit: www.cfdyna.com

Basics Of Multiphase Formula

The basics of multiphase formula involve understanding how different phases move together. Multiphase flow includes liquids, gases, or solids that do not mix. These phases flow simultaneously but remain separate.

This concept applies to many natural and industrial processes. Examples include oil and gas extraction, blood flow, and aerosol sprays. Each phase interacts and influences the others during flow.

What Is A Multiphase Formula?

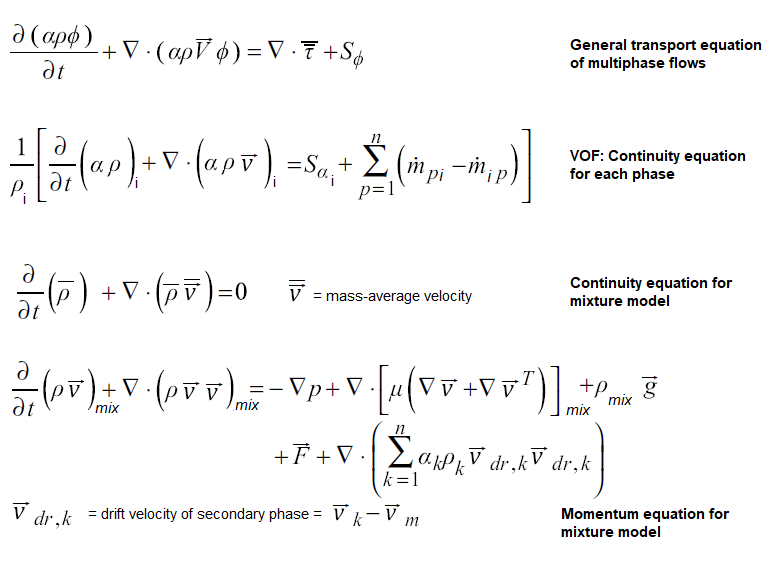

A multiphase formula describes the behavior of two or more phases flowing together. It uses mathematical models to predict flow patterns, pressure, and phase distribution. This helps engineers design better systems and solve problems.

Phases Involved In Multiphase Flow

Multiphase flow contains distinct phases like gas, liquid, or solid. These phases keep their properties and do not mix chemically. The flow shows clear boundaries between the phases called interfaces.

Common Flow Patterns

Different flow patterns occur depending on phase properties and flow conditions. Examples include bubbles in a liquid or droplets in a gas. Each pattern affects how the phases move and interact.

Importance Of Multiphase Formulas

Multiphase formulas help predict how phases behave in pipelines and reactors. Accurate predictions improve safety and efficiency in industries like oil, chemical, and environmental engineering. They also help prevent equipment failure.

Credit: in.palmers.com

Types Of Multiphase Flows

Multiphase flows involve the movement of two or more phases together. These phases can be gases, liquids, or solids. Different types of multiphase flows exist based on how these phases interact and move. Understanding these types helps in many industries like oil production and chemical processing.

Bubble Flow

Bubble flow occurs when gas bubbles move through a liquid. The bubbles are usually small and spread out. This type is common in water treatment and chemical reactors. It affects how gases dissolve in liquids and how they mix.

Slug Flow

Slug flow has larger gas pockets separated by liquid slugs. The flow looks like alternating segments of gas and liquid. This flow type happens in pipelines and oil wells. It causes pressure changes and can affect equipment performance.

Annular Flow

Annular flow features a gas core surrounded by a liquid film. The liquid forms a thin layer on pipe walls while gas flows in the center. This type appears in high-speed gas-liquid flows. It influences heat transfer and pressure drop.

Dispersed Flow

Dispersed flow contains small droplets or solid particles spread in a continuous phase. For example, liquid droplets in gas or solid particles in liquid. This flow type occurs in sprays and dust storms. It impacts mixing and chemical reactions.

Stratified Flow

Stratified flow happens when phases flow side by side without mixing. Liquids and gases separate into layers due to gravity. This flow type is seen in horizontal pipes or natural streams. It affects flow stability and phase distribution.

Key Benefits Of Multiphase Formula

The multiphase formula offers several important benefits across many fields. It helps manage the interaction of different substances in one system. Each phase retains its own properties while working together.

This formula improves efficiency and control in industrial processes. It supports better product quality and reduces waste. The ability to handle multiple phases at once saves time and resources.

Improved Efficiency In Processing

Multiphase formulas allow simultaneous handling of solids, liquids, and gases. This reduces the need for separate processing steps. It speeds up production and cuts operational costs.

Enhanced Product Quality

Maintaining distinct phases ensures materials keep their essential traits. This control leads to more consistent and reliable products. Quality remains high even with complex mixtures.

Better Resource Management

Using multiphase formulas reduces material loss during processing. It minimizes waste and optimizes raw material use. This approach supports more sustainable production methods.

Greater Process Control

Operators can monitor and adjust each phase independently. This flexibility helps prevent issues like phase separation or clogging. It allows for finer tuning of process conditions.

Wide Industrial Applications

Multiphase formulas apply to many industries, from oil to food production. They help manage complex flows in reactors, pipelines, and mixers. This versatility makes them valuable in various settings.

Common Applications

Multi Phase Formula finds use in many industries and daily processes. It helps manage flows involving different substances together.

These formulas guide how to handle liquids, gases, and solids moving as one system. Their use improves safety and efficiency.

Oil And Gas Industry

In oil fields, oil, gas, and water flow together in wells. Multi Phase Formula helps predict how these move and separate. This supports better extraction and transport.

Chemical Processing

Chemical plants mix gases and liquids in reactors. Multi Phase Formula designs these reactors for better reactions. It controls flow and mixing of different phases.

Environmental Engineering

Pollutants in air or water often form multi-phase flows. These formulas help model how particles spread or settle. This aids in pollution control and cleanup.

Food And Beverage Production

Food processing uses multi-phase flows like emulsions or foams. Multi Phase Formula assists in creating stable mixtures. It ensures quality and texture of products.

Pharmaceutical Industry

Drugs often mix solids and liquids during production. Multi Phase Formula manages these flows to keep consistency. It helps in making safe and effective medicines.

Challenges And Considerations

Understanding the challenges and considerations of a multi phase formula is essential. These formulas involve multiple steps or layers, which can complicate their development and use. Careful thought is necessary to ensure effectiveness and safety.

Several factors affect the performance and stability of multi phase formulas. Manufacturers and users must address these to achieve the desired results.

Complexity In Formulation

Creating a multi phase formula requires mixing different ingredients carefully. Each phase has its own properties, which can affect how they combine. Balancing these phases to avoid separation or instability is difficult.

Stability Issues

Phases in the formula can separate over time, causing the product to lose effectiveness. Preventing this requires special techniques and stabilizers. Monitoring the formula during storage is important to maintain quality.

Compatibility Of Ingredients

Not all ingredients work well together in a multi phase formula. Some may react or cause changes in texture and color. Testing ingredient compatibility helps avoid these problems early in development.

Cost And Production Considerations

Multi phase formulas often need more complex manufacturing processes. This can increase production costs and time. Efficient production planning and quality control are necessary to keep costs manageable.

Consumer Experience

Users expect easy application and consistent results. Multi phase formulas can sometimes feel different or require special handling. Designing for good texture and usability improves customer satisfaction.

Credit: in.palmers.com

Frequently Asked Questions

What Are Multiphase Flows?

Multiphase flows involve simultaneous movement of two or more distinct phases, like liquids, gases, or solids. These phases interact dynamically and maintain separate interfaces. Multiphase flows appear in industries such as oil, gas, chemical engineering, and natural processes like blood circulation and aerosols.

What Do You Mean By Multiphase?

Multiphase means the simultaneous flow of two or more distinct phases, such as liquids, gases, or solids. These phases do not mix chemically and interact dynamically. Multiphase flow occurs in natural phenomena and industrial processes like oil production and biological systems.

What Is The Flow Pattern Of Multiphase?

The flow pattern of multiphase involves distinct phases like gas, liquid, or solid flowing together. Patterns vary as bubbles, droplets, or slugs, influenced by phase interactions and flow conditions.

What Are Examples Of Multiphase Materials?

Examples of multiphase materials include oil-water mixtures, aerosols, blood, and concrete. These materials contain distinct solid, liquid, or gas phases interacting simultaneously.

What Is A Multi Phase Formula In Simple Terms?

A Multi Phase Formula describes how different phases like gas, liquid, and solid flow together.

Why Is Multi Phase Flow Important In Industries?

It helps design pipelines and equipment for safe, efficient handling of mixed substances.

How Do Different Phases Interact In Multi Phase Flow?

Phases affect each other’s movement, pressure, and distribution through dynamic interactions.

Conclusion

Understanding the multi phase formula helps explain how different substances move together. It shows how liquids, gases, and solids interact without mixing. This knowledge supports better design in industries like oil, chemicals, and biology. Seeing flow patterns and phase boundaries aids in predicting system behavior.

Knowing these basics makes complex processes easier to grasp. This foundation is useful for students, engineers, and curious minds alike. Exploring multiphase flow reveals the hidden dynamics in many natural and industrial settings.

Skip to content

Skip to content